FOUNDATION CRACK REPAIR | CALGARY

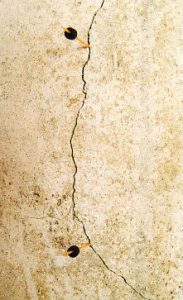

Cracks can cause losing structural integrity and major injury to your building’s foundation cracks. Typically due to drying, shrinkage, or thermal movement and may result in serious problems. Oftentimes, a foundation crack will widen as time passes, resulting in water seepage and possibly even losing structural integrity causing major injury to everything in your downstairs room.

The technique that wizard crack repair uses to fix concrete cracks depends on the location and the size of the crack.

Foundation repairs may be divided into two classes:

1. Wide concrete cracks

2. Narrow concrete cracks.

FOUNDATION REPAIR

DRIVEWAY

PROFESSIONAL, COURTEOUS AND COST EFFECTIVE SERVICE

WHY CHOOSE WIZARD?

Providing 2 years warranty for all concrete crack repairs

- Garage pad

- Side walk

- Driveway

- Steps

Lifetime guarantee

- Foundation crack repair

No hidden costs and honest service

We specialize in the following services:

Basement wall and foundation cracks repair

Driveway concrete crack repair

Sidewalk concrete crack repair

Garage pad crack repair

We offer :

Free Drainage Analysis with Work

Lifetime Guarantee

24-Hour Emergency Service

WCB and Liability Coverage

CALGARY’S CONCRETE CRACK REPAIR SPECIALISTS

COMMERCIAL FOUNDATION REPAIR

Every structure’s foundation varies but with regards to repairs, strategies used are standard. They include:

1. Use of epoxy injection: This is considered the simplest form of repair and is mainly done internally. It involves cleaning after which injecting epoxy paste and the resin which helps it to bond tightly to the crack.

2. Polyurethanes: These are 2-part polymers that are expansive and flexible. The hydrophilic type attracts water in its curing as the hydrophobic polyurethane repels or displaces water the same as epoxy in the cracks.

You will find other procedures that are accustomed to restore the structural integrity of the home’s foundation, but the choice is determined by your contractor’s assessment. Whatever the situation, never take these seemingly small defects lightly. Instead, promptly phone a foundation crack repair professional to initiate immediate restoration.

Our Testimonial

WHAT PEOPLE SAY?

AVERAGE RATING

We’re Using Polyurethanes

If you find concern about material leaking out a corner of a crack polyurethane foams must be used. These elastomenc, fast-selling foams are powerful alternatives for applications involving crack sealing (waterproofing) and not structural repair. Because of their elastomenc nature, they are able to accommodate slight concrete movement hence the seal stays intact They also set out to harden and foam within units of injection. These reduce the prospect of the material flowing out associated with an injected crack.

- Polyurethanes Contribute to Sustainability

- Resources & Documents Library

- Economic Benefits of Polyurethanes

Sump Pump Installation

The sump pump is the Achilles’ bottom in terms of waterproofing your basement, keeping a sound foundation and bypass foundation split repair. If it goes straight down, you may soon find your ping pong table buoyant in a pond. Here’s what you should observe in terms of sump pump arrangement.

- No special Machineries

- We use Radon Tester for basement cracks

WHY LOW-PRESSURE INJECTION?

Low-pressure injection moulding provides standard low-cost connector components. Today’s competitive marketplace is certainly forcing manufacturers to re-assess all components of production – from garbage affecting manufacturing lead point in time, to capital equipment. Time-to-market, production flexibility and cost containment are very critical elements to be treated while ensuring you encounter customers’ performance requirements. Low-pressure injection moulding utilizing hot melts is one manufacturing method that can improve existing processes and fulfill the needs of today’s ever-changing systems landscape.

Low-pressure moulding is bringing injection-moulding capacity to applications previously unserved as a consequence of either cost or refinement challenges. The low-pressure injection moulding progression utilizes polyamide resins to give low-pressure filling of moulds. Material offers many benefits to manufacturing costs together with finished product performance. Injection moulding isn’t cost-prohibitive or simply inflexible to product changeovers. Together with, sensitive electronic components can now experience the protection and security provided by over-moulding.

- Moisture permeates the tiny breaks in the concrete

- Foundation stabilize

High Pressure Epoxy

In case you are unsure, you need to execute a simple moisture vapour transmission (MVT) test on the surface of your concrete just before a coating is applied. The coating, as well as your work, may be destined to fail in the event you don’t.

As hard and dense as concrete is conduct a test, it is actually very porous. Moisture beneath the slab will permeate to the surface of the concrete. Because coatings such as epoxy are impermeable, nor breathe, water vapour and moisture can’t paw from the coating. The build-up of this kind of moisture under the coating can lead it to peel or delaminate. Though colour will breathe, anything greater than light moisture vapour can cause paint to peel as properly.

Get In Touch

QUICK ONLINE QUOTE

To receive your Quick Quote by email, please complete the form below. If you have any questions, please call us on 587-284-7796

Areas We Cover!

- Foundation Repair Calgary

- Foundation Crack Repair Calgary

- Concrete Crack Repair Calgary

- Basement Waterproofing Calgary

- Sump Pump Installation Calgary

Contact Us

52 woodbine Blvd SW Calgary,

T2W 4a8

24/7 Emergency Service

info@wizardcrackrepair. com

587-284-7796

Quick Links:

Services

DRIVEWAY CONCRETE CRACK REPAIR

SIDEWALK REPAIR

GARAGE PAD REPAIR

Contact Us

Subscribe Us

Join our mailing list to receive news and

announcements